Paderborn scientists conduct research into dissolving medical devices

Whether bone screws, plates or stents – implants are inserted in patients in hospitals throughout Germany every day. However, it is not uncommon for these implants to have to be removed again in a subsequent operation, for example in the case of children and adolescents, whose bones are still growing. But every subsequent operation carries a risk and costs money. In 2010, 180,000 operations were performed in Germany for the sole purpose of removing orthopaedic implants. This makes the removal of implants the fourth most common orthopaedic operation in Germany. One possible solution: stents and co. that degrade after a few weeks or months – depending on the relevant application – and are metabolised by the body. Such medical devices are, however, still rarely used. An interdisciplinary team at Paderborn University is currently working on the development of effective implants.

The challenge is to find materials that are stable enough and last as long as the body needs them in order to heal, and that then degrade easily and, above all, in a controlled manner. Research in the field currently focuses on iron, magnesium and zinc. Pure iron dissolves extremely slowly, and magnesium extremely quickly. Zinc corrodes well, but its low tensile strength often limits its application. Researchers worldwide are searching for the perfect alloy, the optimal implant for the respective application. In addition to the relevant application, biocompatibility (i.e. compatibility with the body), production methods and manufacturing costs also need to be taken into account. The German Research Foundation (DFG) is funding various projects in the field, a number of which are being carried out in Paderborn.

Putting iron alloys to the test

Iron alloys have been the subject of research at Paderborn University for several years now. In their collaborative work, scientists in the Technical and Macromolecular Chemistry research group and Department of Materials Science have decided to focus on the metal iron. The team is specifically investigating iron-manganese (FeMn) alloys, as pure iron would take far too long to dissolve. “We see enormous potential in iron-manganese alloys, as the combination of mechanical properties, biocompatibility and corrosion rates are promising,” says Dr Adrian Keller. But: Anyone who wants to develop suitable medical materials must also, of course, consider the physiological environment. To this end, body fluids, for example, are simulated and the samples tested in experiments.

In a study (doi.org/10.1002/maco.202112841) recently published in scientific journal ‘Materials and Corrosion’, Paderborn scientist Jingyuan Huang and her colleagues analysed the surface corrosion, i.e. the desired dissolution rate of the material, and fatigue behaviour of the alloy in a simulated body fluid. To simulate the tissue surrounding the bone in the body, they applied a hydrogel to the sample. They found that although this ‘tissue layer’ does not significantly affect the corrosion rate, it does prevent the precipitation of corrosion products, such as oxides and phosphates, on the iron surface.

Proteins influence the corrosion rate

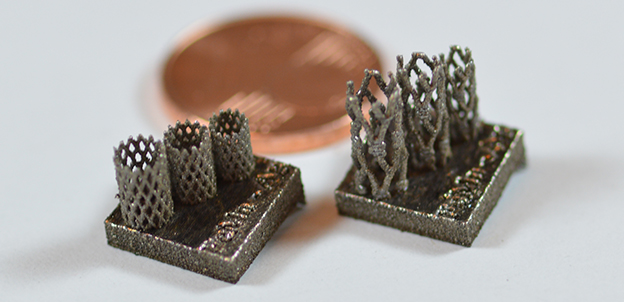

Colleagues from the Department of Materials Science are collaborating with the team from the Technical and Macromolecular Chemistry research group on the production and analysis of novel alloys. For a publication in scientific journal ‘Corrosion Science’ (doi.org/10.1016/j.corsci.2022.110186), the mechanical engineers produced implants using laser powder bed fusion (LPBF). “In this process, metallic powder is deposited on the build platform, layer by layer, and melted locally by a laser. The product is therefore built up layer by layer, enabling the creation of extremely complex, filigree structures with partly new and innovative materials,” explains Dr Kay-Peter Hoyer.

In this study, the researchers compared samples of pure iron with both a rolled FeMn alloy and a sample manufactured by means of LPBF. The LPBF-manufactured FeMn alloys showed the highest corrosion rate. A further focus was on the processes on the surface of the implants. This is because body fluids such as blood plasma contain proteins, for example, which can interact with the surface of the implant. Keller explains: “We discovered that both the microstructure of the implants and the surrounding proteins influence the degradation rate of the alloys. We believe that the LPBF-manufactured samples have more chances of being used in the future.”

Biodegradable implants are therefore nothing new, but more research is still needed in order to develop the perfect device. Scientists from Paderborn are working on this. “This is exactly what makes the research so exciting: there’s still so much to discover, and it’s going to take us time to understand the complex processes – at the interface between the implant and the respective environment, for example. What’s particularly important for me is that this is not just research that’s exciting to work on in the lab, but also research that is relevant for the health of our society,” sums up Keller.

About World Health Day

World Health Day was first declared on April 7, 1954. The aim of the World Health Organization, which officially hosts the day, is to inform the public about health issues. More information can be found on the World Health Day website.